FAQ

Minimum Pilot Qualifications for the RJ85, Q400 (Dash 8-400AT), CL-415

- Valid Commercial Pilot certificate

- Multi-engine land (MEL) or Multi-engine sea (MES) ratings

- 2000 Total Time flight hours – Fixed Wing

- 500 hours Multi-engine – Fixed Wing

- 250 hours in aircraft over 12,500 lbs.

- 100 hours in aircraft in preceding 12 months – Fixed Wing

- 75 hours, actual or simulated, instrument flight

- FAA Class II medical certificate

Unmanned aircraft and rotor wing flight time does not count toward minimum.

A & P mechanics will be responsible for maintaining our CL-415, Dash 8-400AT, and Avro RJ-85 firefighting aircraft, through tasks such as inspection, trouble shooting, repair, modification and functional testing per Aero-Flite, Inc. policies, procedures and FAA requirements.

Qualifications:

- Interested applicants must hold a valid A & P license, driver’s license, and current passport.

- Must be able to enter other countries and complete a security background check.

- Must be able to lift up to 70 lbs. and be in good physical shape in order to work off of two story scaffolding.

- Applicant must have their own hand tools.

- Experience on turbo prop and turbo fan engines would be an asset to this position.

Tools:

All Mechanics must supply the following tools while employed with Aero-Flite, Inc. as an A & P Mechanic. All tools must be of professional quality.

Required Tools after 90 Days:

- Applicant must have their own hand tools.

| Required Tools at Time of Hire: | |

|

|

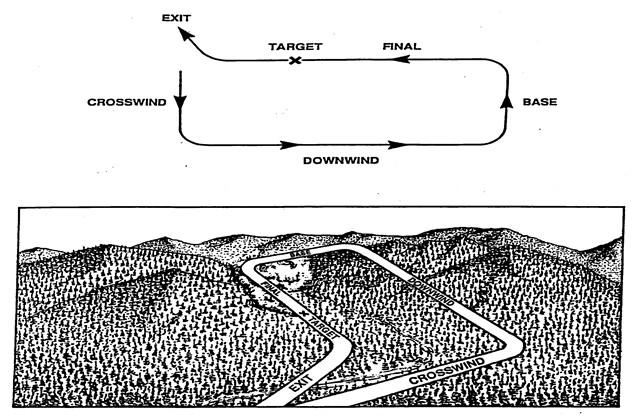

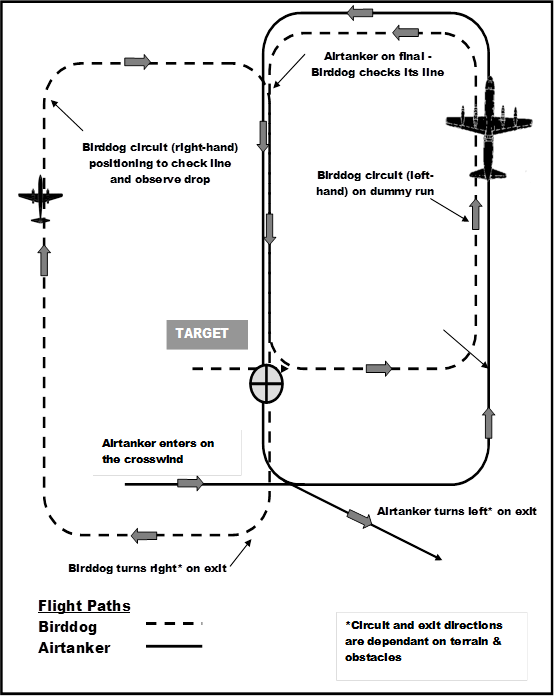

The circuit or traffic pattern over a fire is similar to that used over an aerodrome [airports]. An airtanker drop circuit is made as if the fire is a runway [airstrip] and the aircraft are in the circuit. Since landings are made into the wind, the terminology makes it seem like the wind is blowing towards the Airtanker on final. In actual fact, the wind can be blowing from any direction. Because of this, the leg opposite the target and heading 180° to final is called downwind. The turn would be left or right base and then final, which is heading straight toward the target. These terms [crosswind, downwind, base, final, and exit] are important as they quickly identify an aircraft’s position in relation to the target. Left hand circuits are preferable as the pilot[s] can keep the target in sight at all times.

2. Over the Fire – Target Identification Techniques

Low level passes are made over the fire by the Birddog on all intended airtanker runs. The Birddog team will determine the following for each run:

· Elevation

· Direction of run

· Direction of approach [left or right hand circuit]

· Placement of drop

· Correction for wind drift

· Type of drop

· Hazards-snags power lines, turbulence, etc.

· Escape routes

The Birddog team will make the intended airtanker runs to determine the feasibility of approach and safe exit routes. They will check the target elevation and note hazards.

Wherever possible, right hand orbits will be used in order for the Air Attack Officer to have the fire in sight at all times. In this position, the Air Attack Officer can readily note any changes in fire behavior which can influence his drop sequence.

Loaded airtankers have limited maneuvering and climbing capabilities. These low level passes must simulate the flight of the airtanker in a manner that will allow the airtanker to hold the load over the fire and exit safely.

When the airtanker arrives overhead of the fire, the Birddog Pilot or Airattack officer will verbally identify the target to the Airtanker Pilot by providing the information listed above.

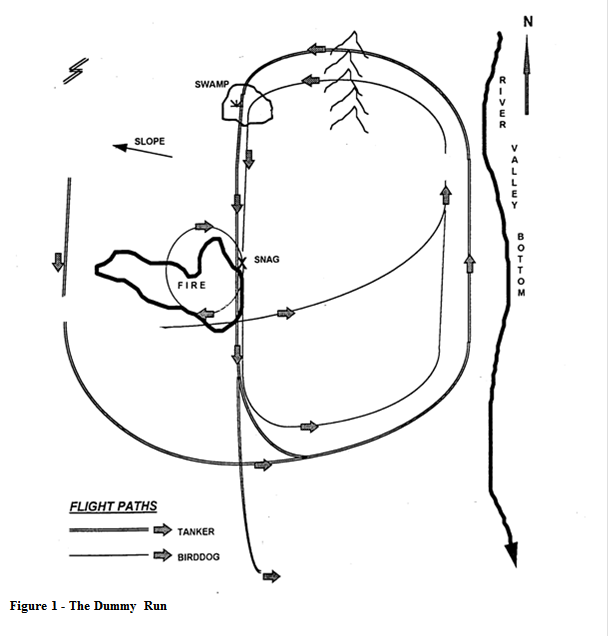

2.1. The Dummy Run

On confirmation of the airtanker being in position to observe the run, the Birddog team will use the dummy run to demonstrate the run and pinpoint the target. The Birddog Pilot or Air Attack Officer will talk through the circuit and will describe:

· Downwind heading

· Ridge crossing elevations

· The turn from base to final

· Heading to the target

· Reference points [if available]

· Drop height

· Target description

– type of drop

– where to start

– end point

· Hazards

· Escape route[s]

The Air Attack Officer will activate the siren [warble/yelp mode]. This will alert the ground crew as to an impending bombing run and where it is to be dropped. The Air Attack Officer is responsible to ensure the ground crew is out of the path of the intended drop.

This technique is normally used for the first airtanker on a specific run. It should not be necessary to repeat the procedure for each drop unless there is:

· A change in direction or target elevation.

2.2 The Bombing Run

Once the target has been identified, the Birddog aircraft has a number of options in which to positively control the bombing run after the airtanker has been cleared to make the run.

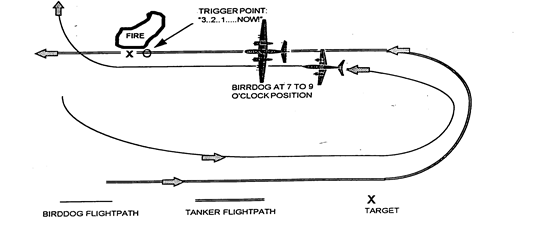

The following illustration describes a simple yet typical bombing run however there are variations to the typical or generic bombing run. These are described as follows:

The Follow Around

In this scenario, the Birddog aircraft will fall in behind the airtanker, a little to the left and a little high. This allows the Air Attack Officer the best view of the drop and keeps the Birddog up and out of the airtanker’s wake turbulence. This is what is called the 7 o’clock position.

The distance to follow behind the tanker should allow for the AAO to view the release of the retardant and still be able to see where on the ground the load settles. This distance will vary with the environmental conditions (I.e. winds) and the drop height.

This procedure provides the Air Attack Officer an unobstructed view of the run and drop which will allow him/her to make last-second corrections to the line on final and be able to make the drop assessment.

Radio transmissions on a wildfire are limited during the run to facilitate birddog and airtanker interaction. Instructions are kept short and clear.

When the airtanker turns onto final, radio silence is maintained unless:

· The line needs correction.

· Obvious concern exists regarding safety [e.g. ground crew not clear, unannounced aircraft in conflict, etc.]

The siren is used during all new runs on different parts of the fire to warn ground crews. Enough time must be allowed to ensure that there is enough warning for the crew to safely exit the drop area.

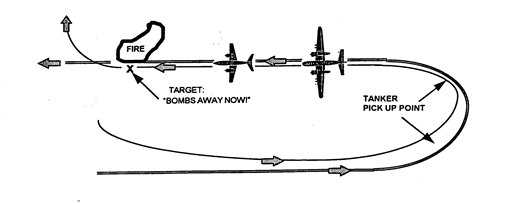

The Lead In

The lead in is normally used when the line and trigger point are difficult to see or describe due to visibility or lack of references. The following is the sequence used for the lead in:

· The Birddog pilot manoeuvres in front of the tanker on the downwind or base leg of the circuit.

· At this time, the Birddog pilot will give a brief run description that will include any hazards and the exit.

· The airtanker pilot controls the Birddog speed by radio so the Birddog does not “walk away” from the airtanker or the airtanker closes in on the Birddog.

· As the Birddog pilot approaches the target, he/she will count down and say, “3, 2, 1, bombs away now” to announce the start point.

· The airtanker pilot will advise that he/she is on final and armed for the type of drop requested.

· Following the announcement, the Birddog will pull up hard and make a 180° turn away from the fire’s edge to parallel the final run while maintaining a safe distance from the airtanker.

· This manoeuvre puts the Birddog in position for the Air Attack Officer and/or Birddog pilot to observe the drop and make an assessment.

Maintain radio silence when the Airtanker is on final unless safety is a concern or the load needs to be held.

The Called Shot

This method is used when the airtanker pilot understands the line but cannot identify the actual target or trigger point.

The Birddog team will brief the terminology with the airtanker pilot prior to the airtanker approaching the target. In carrying out this manoeuvre, the Birddog aircraft fall in alongside the airtanker on the final run.

Full consideration must be given to the airtanker “wing tip vortices” and the climb-out capabilities of the airtanker in use.

As the target is approached, the Air Attack Officer or Birddog pilot will begin the called shot countdown “3, 2, 1, bombs away NOW”. The airtanker pilot triggers the load on hearing “NOW”.

The assessment is always a “bull’s eye” for the airtanker pilot.

Differences in elevation of lateral position between the Birddog and tanker may create a distorted view for the Air Attack Officer. This parallax may cause the trigger point to be called too early or too late.

It is advisable for an AAO to incorporate this technique into a group practice and also count down regular drops in his/her head to prepare for the eventual called shot.

Orbit and Direct

The Birddog aircraft orbits over the fire where it is clear of smoke and there is a good view of the fire area.

A verbal target description is given to the airtanker with the Birddog positioned overhead.

This method is normally used with skimmer airtanker[s] that are conducting sustained action and the airtanker pilots have had previous dummy runs or lead-ins through the flight path.

A liquid fertilizer grade ammonium polyphosphate (11-37-0), combined with guar gum, color package and a corrosion inhibitor. It is shipped to the various tanker bases as a liquid concentrate and blended on demand into the airtanker. The mixing ratio of water to liquid concentrate retardant is generally 5.5:1

The active salt permits pyrolysis at a lower temperature and promotes the formation of water, carbon and char at the expense of flammable gases. Wood itself does not burn; rather, the gases that are produced through pyrolysis ignite when the” flash point” is reached and provide the additional heat required to produce additional flammable gases. In summary, long-term retardants inhibit flaming and glowing combustion and remain effective after the water portion is removed [i.e. evaporation]”.

Wildland Class A fire fighting liquid concentrates consisting of a surfactant, corrosion inhibitor and stabilizers. A brief description of all Class A foams is detailed below:

Foam is made when air is forced into water containing a foam concentrate. The air is forced into an Airtanker load during the drop process [after the load is released] and forms a “foam blanket” after settling on the ground.

One of the primary effects of this foam blanket is to smother and cut off the fire from oxygen and air supply. As the blanket absorbs the heat from the fire, it will slowly break down into a liquid state. The rate of breakdown is in direct proportion to the heat to which it is exposed. The water released from the blanket retains wetting and penetrating qualities and continues to exert a cooling effect.

When applied in adequate quantities foam resists disruption due to wind or heat and to flame attack and is capable of resealing. These properties last for varying periods of time depending on the foam solution mixture and the fire environment.

Unlike long term retardant, once the water evaporates from this “short term retardant” the suppressing action ends.

The enhancing fire fighting ingredients are the surfactant and stabilizer components of this product [water is the active ingredient]. Expansion is another measurable property and is described after the stabilizer description. The following briefly describes how these components function when added to water:

1.1. Surfactant

This component causes water to soak into the fuels.

- Surfactant is a surface-active ingredient that has the ability to decrease the surface tension of water.

- Also known as a wetting agent.

- Surface tension of water is decreased when only a small amount of concentrate [i.e. 0.3%] is added.

- Has a greater ability to penetrate because less run off occurs, as more of the water soaks into the surface of woody material.

1.2. Stabilizer

This chemical increases the stability of the foam [i.e. the life of the bubble].

- Stability of the foam is referred to as the percentage of drain time or the time in minutes for water to drain from the foam bubble.

Mixtures for aerial application range from:- 0.1% [wet/fluid consistency] to

- 0.3% [dripping consistency] and

- 0.5% [dry consistency].

1.3. Expansion

Expansion is the ratio of the volume of foam to the volume of solution used to make the foam. Most foam used for wildfire suppression is in the range of 10:1 to 20:1. For example, one gallon of solution can be expanded to yield 10 to 20 gallons of foam

Listed below is a description of foam at various consistencies and their general firefighting uses:

- Dry foam holds its shape, adheres well, and slowly releases the water contained in the bubbles, making it a good insulator. This consistency should be used primarily as an insulating blanket.

- Example: If ground follow up is going to be delayed and 0.3% [dripping] loads were dropped on the fire, drier consistency foam [0.4%] can be applied to increase the life time of the foam blanket.

Dry foam has a tendency to be intercepted by the tree canopy and releases water slowly.

- Example: If ground follow up is going to be delayed and 0.3% [dripping] loads were dropped on the fire, drier consistency foam [0.4%] can be applied to increase the life time of the foam blanket.

- Dripping foam exhibits characteristics intermediate in performance between wet and dry foams. This consistency at approximately 0.3% is considered the most ideal fire fighting foam. This mixture penetrates the tree canopy; adheres to both vertical and horizontal fuels; and forms an insulating blanket that is visible from the air.

- Wet foam is fluid, flows easily and releases water quickly and is a good coolant. Suggested uses for wet foam are as a wetting agent for mop-up with close ground support, and initial drops on a fire to penetrate the canopy and wet the fuels. If ground support is going to be delayed a second drop with a drier foam consistency should be made to seal the blanket.

Short term retardants are usually applied directly to the base of the fire and can easily be termed as suppressants.

When relative humidity is low and fire intensity is high the effectiveness of the foam blanket is short lived.